- Our Models

- ServicesHesitant in service?

Get in touch with us with your business problem and we’ll consult you on the suitable service solution.

- ConsultantsApplicationsLegacy Support

- Industries

- Our Company

About Us

About UsLearn more about our HireDynamicsDevelopers portal and the team behind it.

Case StudiesRead successful stories from our clients across various industries.

ServicesFind the right service according to your specific business needs.

- Locations

- Our Models

- ServicesHesitant in service?

Get in touch with us with your business problem and we’ll consult you on the suitable service solution.

- ConsultantsApplicationsLegacy Support

- Industries

- Our Company

About Us

About UsLearn more about our HireDynamicsDevelopers portal and the team behind it.

Case StudiesRead successful stories from our clients across various industries.

ServicesFind the right service according to your specific business needs.

- Locations

Benefits and Features of D365 F&O Planning Optimization for Manufacturing

Updated: May 30th, 2025 by Ivan Farafonov

This article will help you understand the features you can get if you enable planning optimization in D365 F&O, and how it helps businesses align production and procurement processes with real-time data, ultimately improving responsiveness and reducing costs.

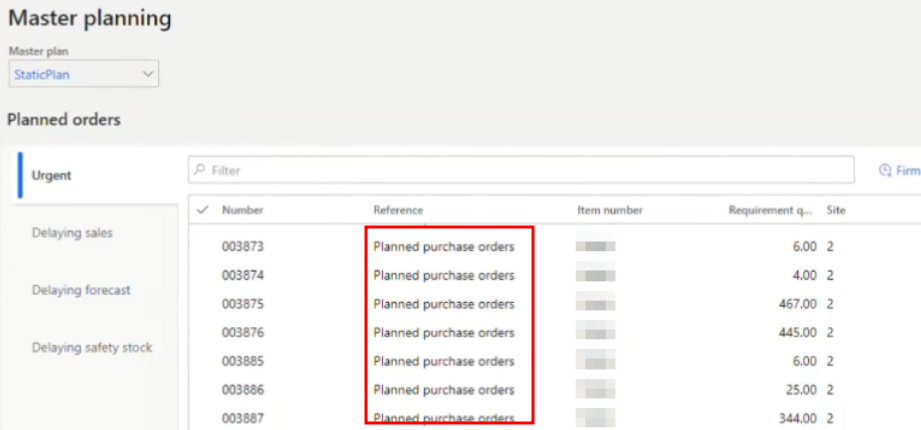

D365 Finance & Operations Planning Optimization Features

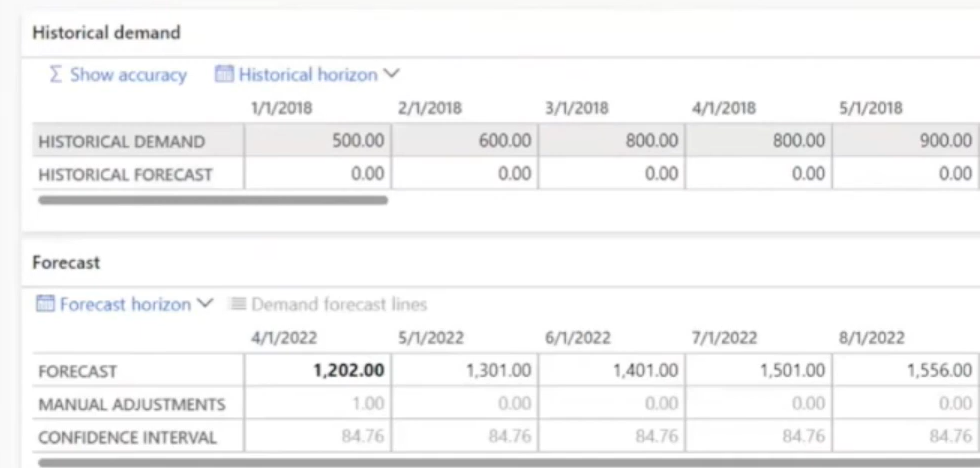

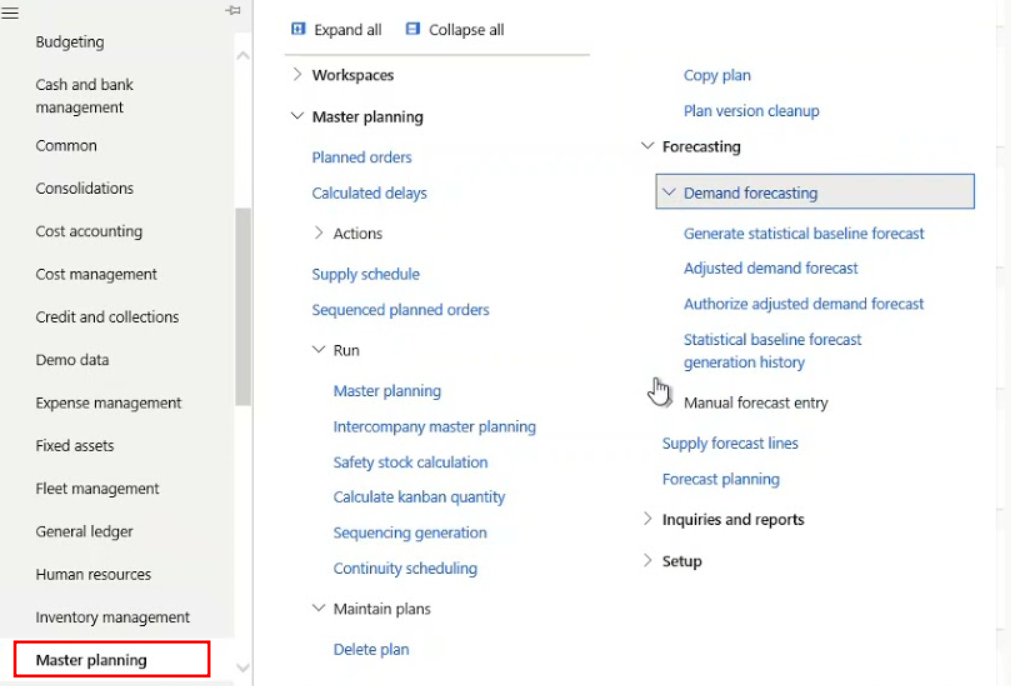

Demand Forecasting

Utilizes advanced algorithms to predict customer demand accurately, helping businesses plan effectively. With planning optimization, D365 F&O products and raw materials consumption starts according to Production and Sales demands. Supports various forecasting methods, like moving averages and exponential smoothing.

Calculated data will help compare actual and forecasting statistics:

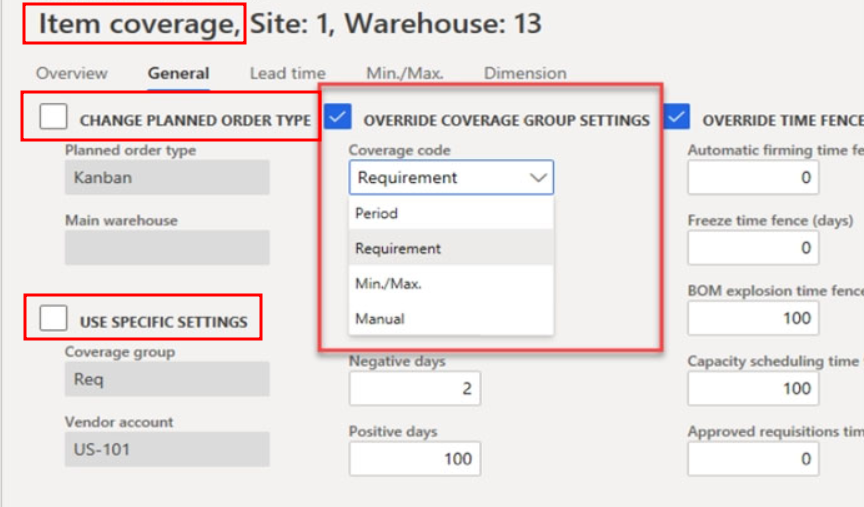

Inventory Management

Optimizes inventory levels by balancing supply and demand, reducing excess stock and shortages. D365 F&O planning optimization might automatically calculate safety stock levels to mitigate stockouts.

Coverage plans and default parameters customization will adapt required calculations to your needs:

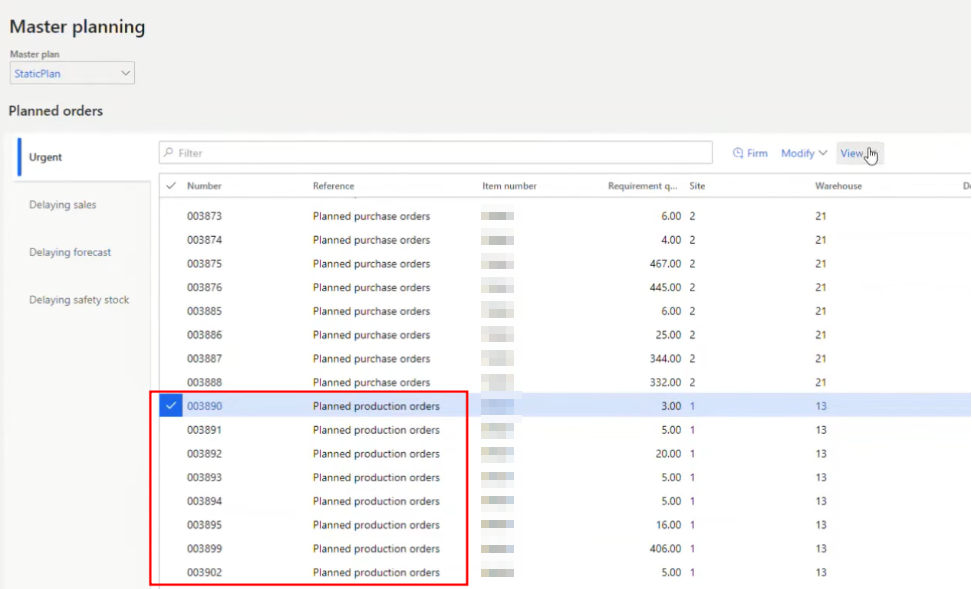

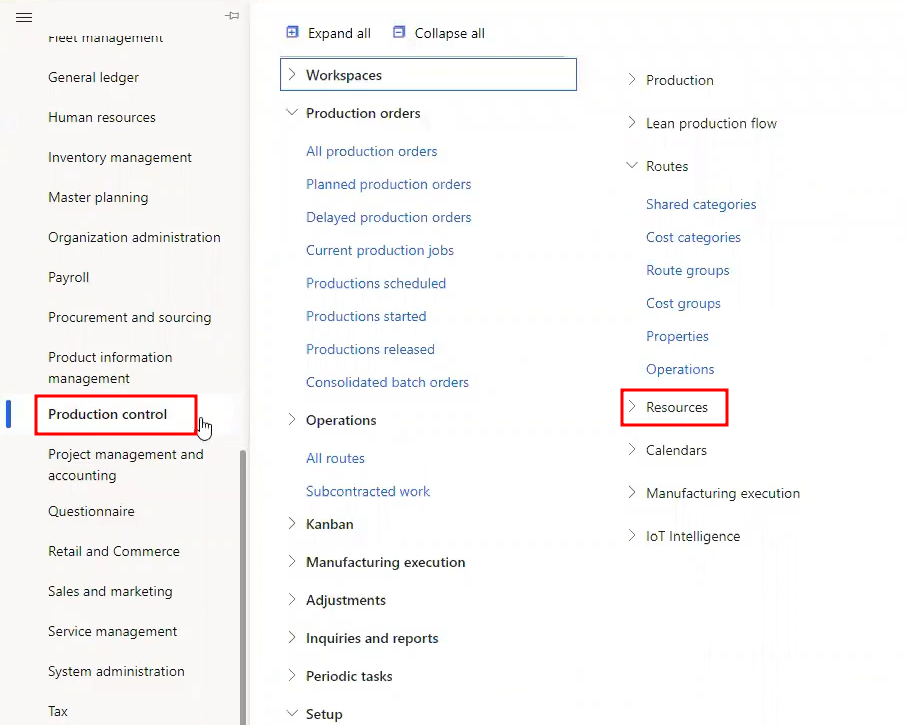

Production Scheduling

Automates scheduling based on demand forecasts, improving efficiency in production processes. Includes Gantt charts that provide a visual representation of the production schedule, making it easier to identify bottlenecks and overlaps.

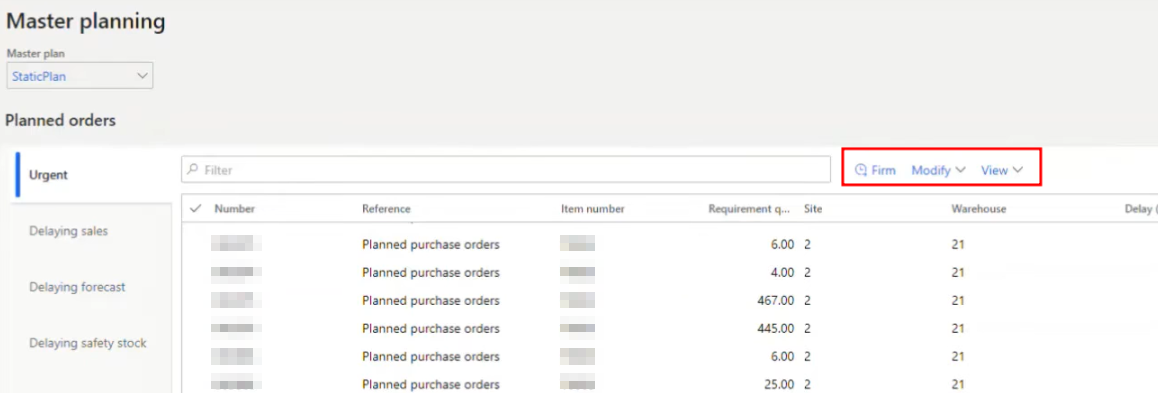

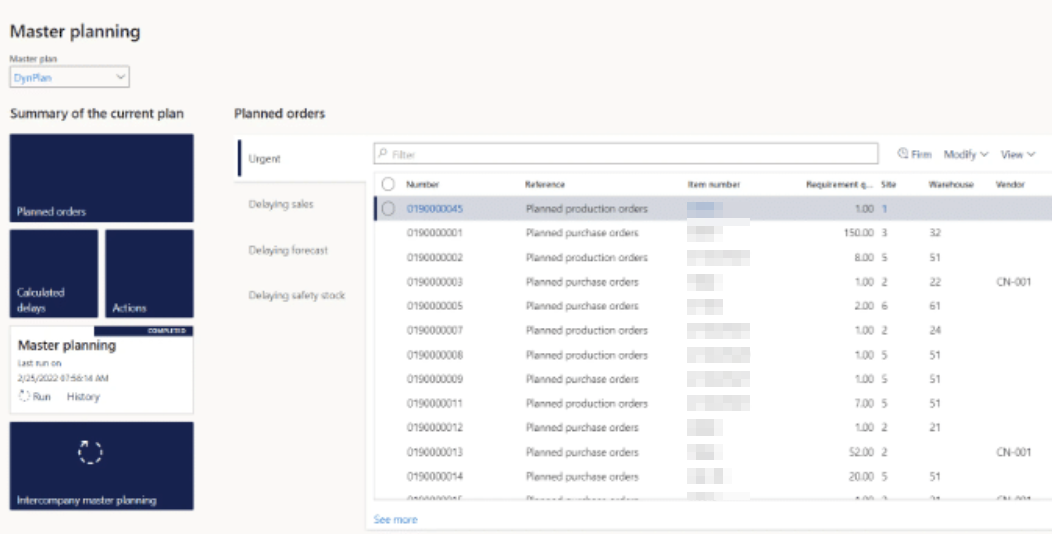

Menu gives a great visibility of Productions orders to analyze and change information according to company plans:

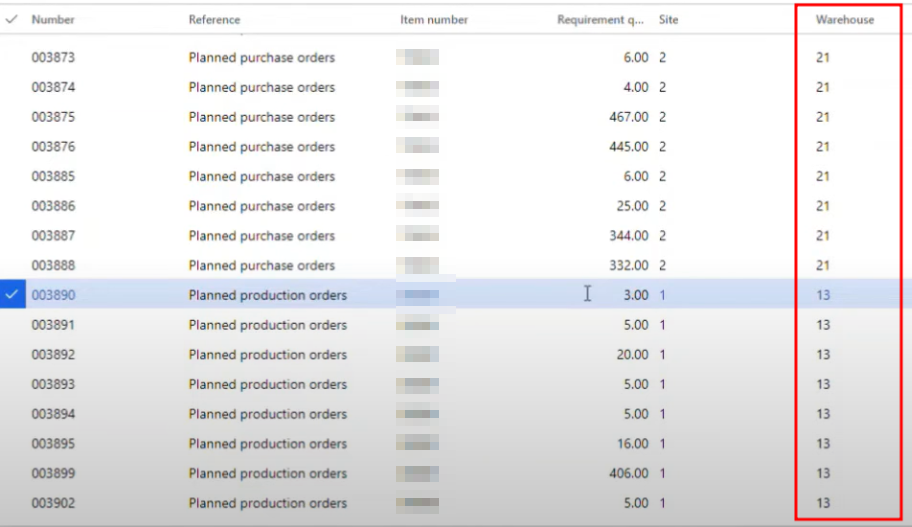

Multi-Site Planning

Supports planning across multiple sites, enabling organizations to optimize resources globally. Allows businesses to set specific parameters (e.g., safety stock levels, reorder points) for each location based on unique operational needs that enable planning optimization D365 work better.

Each order can be scheduled to precise site and location parameters:

Collaborative Planning

Facilitates communication between departments and partners, what helps to reduce time consumption in Intercompany processes. Combines input from various teams to create more accurate demand forecasts, incorporating insights from sales and marketing about upcoming promotions or market trends.

Data Insights in Real-time

D365 planning optimization provides real-time data and analytics, allowing production and purchasing plan adjustments.

Menu actions give a wide range of options in order configuration:

Automated Alerts

Enables notifications for critical events like low rate of materials, ensuring fast management of issues.

User-Friendly Interface

Features an intuitive dashboard that simplifies navigation and enhances user experience. The menu is easy to use and manipulate:

Unlock all Finance and Operations features with Dynamics consultant assistance!

Benefits for Manufacturing Companies

Enhanced Forecast Accuracy

Improves demand forecasting, reducing overproduction and stockouts, leading to better customer satisfaction. Relies on historical and actual data inputs.

Optimized Inventory Levels

Minimizes excess inventory and carrying costs while ensuring sufficient stock for production needs. No need to track inventory manually, you receive all information on one-page analytics.

Increased Production Efficiency

Streamlines scheduling and resource allocation, maximizing manufacturing throughput and minimizing downtime. Calculates required amounts of raw materials for production and finished goods for sales and purchases processes.

Reduced Lead Times

Accelerates response times to changing demand, allowing quick adjustments in production and delivery schedules. Manual input is minimized, which improves speed and makes the process less time-consuming.

Enhanced Decision-Making Strategy

By leveraging AI and advanced analytics, companies can make data-driven decisions, optimizing inventory levels and reducing stockouts.

Cost Savings

Lowers operational costs by reducing waste, improving resource utilization, and optimizing supply chain processes. All waste has been reincluded in new processes automatically, leading to significant cost reductions.

Improved Collaboration

Enhances communication across departments and with suppliers, fostering a more integrated approach to planning. Can be configured in multiple companies, showing the whole chain to Vendors, Manufacturers, and Customers. Also, with the help of Intercompany setups can provide a full SCM cycle throughout all your companies.

Real-Time Visibility

Planning optimization in Dynamics 365 Finance and Operations provides insights into supply chain performance and potential disruptions, enabling proactive decision-making.

Scalability

Adapts to changing business needs, allowing manufacturing companies to scale operations efficiently as demand fluctuates.

Improved General Efficiency

Streamlined processes reduce manual work and errors, leading to faster planning cycles and increased productivity.

Better Risk Management

Identifies potential risks in the supply chain and allows for contingency planning to mitigate disruptions.

Sustainability Improvements

Promotes more efficient resource usage and waste reduction, supporting environmental sustainability initiatives.

Automated Planning Processes

Reduces manual intervention, allowing teams to focus on strategic tasks rather than repetitive planning activities.

Requirements for setting D365 F&O Planning Optimization

The Planning Optimization roadmap in Dynamics 365 Finance and Operations typically consists of several key stages and components aimed at enhancing the planning and supply chain processes. Here are modules and parameters that are included in configuration of master planning optimization that Dynamics 365 Finance and Operations developers can provide.

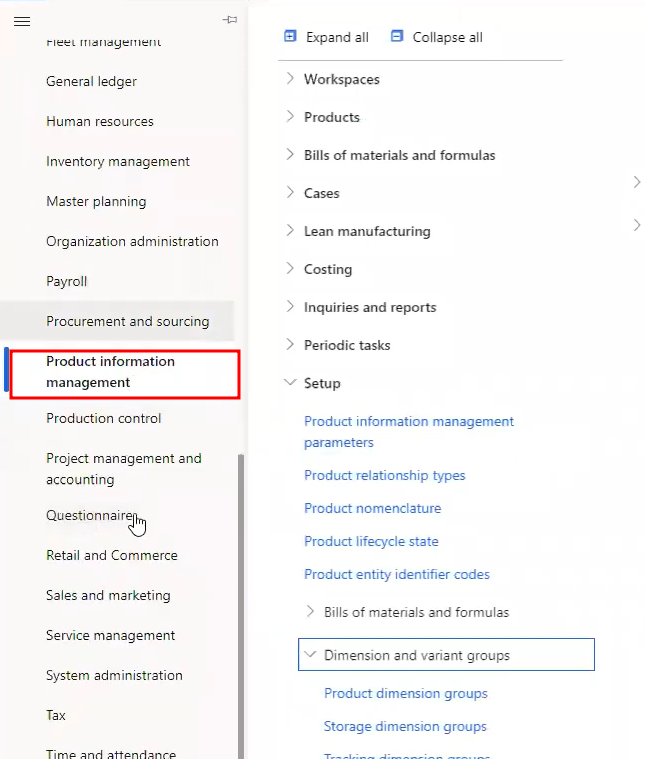

Product Information Management

Includes processes of setups of product coverage and replenishment to keep perfect levels of products in stock.

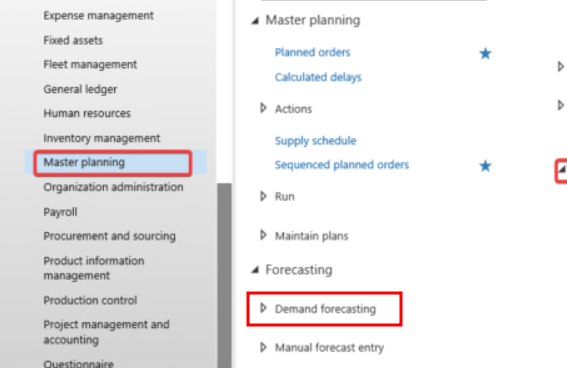

Demand Forecasting

Focuses on forecasting customer demand using historical data and advanced analytics to obtain a better vision for future needs.

Supply Planning

Manages procurement and production schedules to align with demand forecasts, ensuring timely availability of materials and products from suppliers.

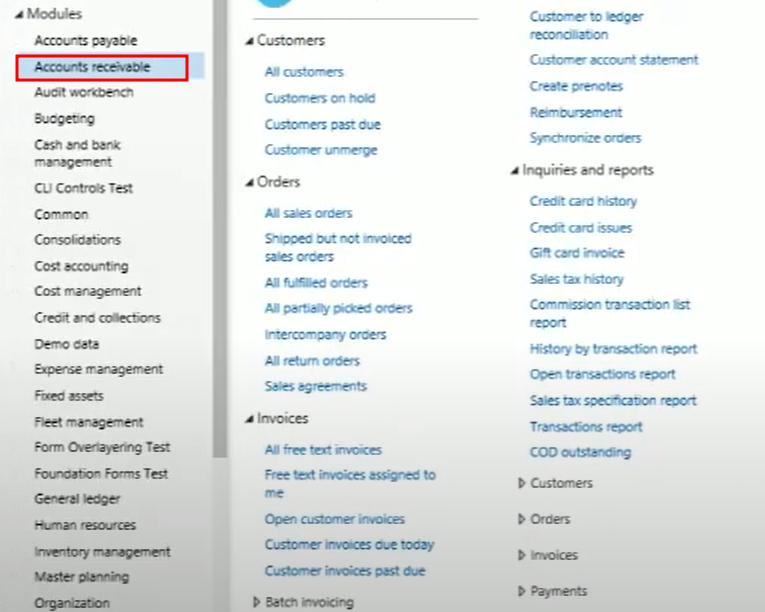

Sales and Marketing

Integrates various business functions to create a cohesive operational plan that aligns supply and demand. Every demand will have a fast and precise response.

Master Planning

Manages the overall planning process, including production, inventory, and procurement planning. Facilitates effective scheduling and resource allocation in manufacturing processes.

Capacity Planning

Assesses and allocates resources to meet production needs while considering constraints that will help to manage the human and machine resources of the company.

Important! MD365 F&O license and product installation is required to run Planning optimization.

Some of Our Finance & Operations Experts

Conclusion

Why should you use Microsoft Dynamics 365 Finance and Operations Planning optimization?

MD365 F&O Planning Optimization provides advanced capabilities for demand forecasting, inventory management, and production scheduling, allowing businesses to respond quickly to market changes. Its data-driven approach enhances decision-making, ultimately improving operational efficiency and customer satisfaction.

Why is it better than master planning?

While master planning focuses on high-level planning processes, Planning Optimization leverages advanced algorithms and real-time analytics for more granular and accurate demand forecasting. This results in better inventory management and more agile production schedules, reducing waste and improving responsiveness.

Is it hard to set up?

Setting up MD365 F&O Planning Optimization requires some initial investment in time and resources, particularly for data integration and system configuration. However, HireDynamicsDevelopers provides robust support and resources, making it manageable for businesses with dedicated IT teams.

What improvements will the company be able to implement with the help of MD365 F&O planning optimization?

Streamline the master planning process, making it faster and more efficient. This can lead to better resource utilization and reduced lead times. Real-time insights into supply chain operations, allowing companies to make informed decisions quickly.

Handle large volumes of data, making it suitable for companies of all sizes. Reduce waste and lower operational costs. Adapt to changing business needs and market conditions, providing greater flexibility in planning and operations. Ability to align the company’s supply with customer demand.

Generalization

MD365 F&O Planning Optimization is ideal for manufacturing companies, particularly those with complex supply chains and varied product lines. It’s also beneficial for businesses looking to improve their operational efficiency, reduce costs, and enhance customer service through better planning and forecasting.

Overall, MD365 F&O Planning Optimization offers a comprehensive solution for businesses seeking to enhance their supply chain management and production processes, making it a valuable investment for organizations aiming for growth and efficiency.

Need help with the Finance & Operations module?

Get in touch with us to hire your consultant!

Outline

Stephan W.

20 Hours / Week

Ruslan P.

10 Hours / Week

Andreea A.

10 Hours / Week

Request Our Services

Get All the Benefits from D365 F&O Planning Optimization for Manufacturing!

Your Partner Recognized in Dynamics Community